Busch TB 26 Banding Machine – Precision Banding for Printing, Packaging, and Logistics

Busch TB 26 Banding Machine – Precision Banding for Printing, Packaging, and Logistics

Description

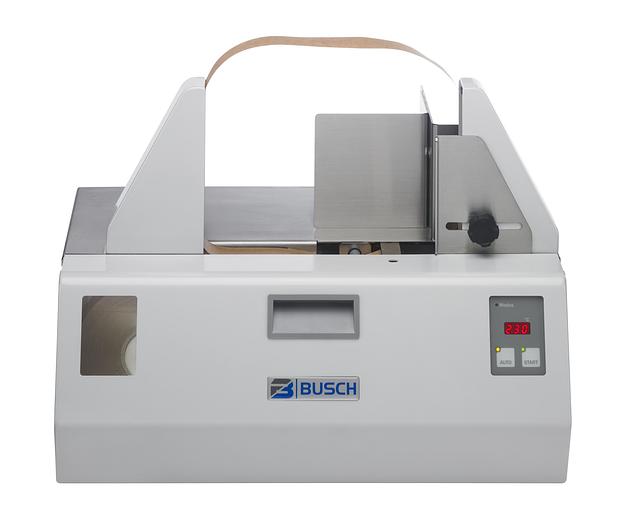

The Busch TB 26 Banding Machine is a cutting-edge, semi-automatic banding solution engineered for the precise bundling of printed materials, packaging, and more. Known for its exceptional efficiency, versatility, and ease of use, this high-performance machine is ideal for the printing, logistics, and packaging industries.

Why Choose the Busch TB 26 I & II Banding Machines?

- Unmatched Versatility: This product is perfect for bundling materials like paper, cardboard, plastics, and other products and offers adaptability across various sectors.

- Adjustable Band Width: Supports bands ranging from 20 – 30mm or 40 – 50mm, allowing for customized bundling to suit your product needs.

- Semi-Automatic Efficiency: Fast cycle times ensure seamless throughput while minimising downtime, boosting productivity.

- User-Friendly Operation: The intuitive control panel simplifies setup and operation, making it suitable for any production team.

- Compact & Durable Design: Space-efficient with a robust build, this machine fits into both small workshops and large-scale production environments.

- Eco-Friendly Banding: It is compatible with sustainable materials like paper and polypropylene bands, making it an environmentally conscious choice.

Key Applications

- Printing Industry: Efficiently bundles magazines, brochures, books, and other printed products.

- Packaging Sector: Secures boxed goods, palletised items, and safe-transit products.

- Logistics: Prepares shipments for easy handling and transportation.

- Retail: Creates attractive product bundles for retail displays and promotions.

Benefits of the Busch TB 26

- Maximized Productivity: Semi-automatic functionality reduces manual labour, increasing efficiency.

- Cost-Effective Performance: Low power consumption and minimal maintenance ensure long-term savings.

- Customizable Settings: Adaptable band widths and materials suit diverse product needs.

- Sustainable Practices: Eco-friendly banding options align with modern environmental standards.

Low-maintenance, High-Reliability Design

The Busch TB 26 is built to last, with easy access to components for quick servicing. Comprehensive customer support options include on-site assistance and remote troubleshooting to ensure minimal disruption to operations.

Upgrade Your Banding Process Today

Experience precision, reliability, and sustainability with the Busch TB 26 Banding Machine. Perfect for bundling, packaging, and logistics, it’s the ultimate solution for businesses aiming to streamline operations and reduce costs.

You can order now or contact us for a free consultation and find out how the Busch TB 26 can revolutionise your production line.

The Busch TB 26 Banding Machine is a high-performance, semi-automatic banding system designed for precisely bundling printed materials, packaging, and other products. Renowned for its efficiency, ease of use, and versatility, the TB 26 is ideal for various industrial applications, including the print industry, logistics, and packaging sectors.

Key Features:

- Versatile Banding: Capable of bundling a variety of materials, including paper, cardboard, plastics, and other items, providing flexibility across different industries.

- Adjustable Band Width: Compatible with bandwidths ranging from 20 to 30mm or 40 to 50mm, depending on the machine, allowing for customisation based on product requirements.

- Efficient Operation: Semi-automatic functionality with a fast cycle time, optimising throughput and reducing operational downtime.

- User-Friendly Interface: An intuitive control panel with easy-to-use settings enables quick setup and adjustment for different tasks.

- Compact Design: Space-saving design with a small footprint suits small and large production environments.

- High Reliability: Engineered with durable long-term-use components, ensuring consistent performance with minimal maintenance requirements.

- Eco-Friendly Options: Compatible with paper and polypropylene bands, offering environmentally conscious bundling options.

Applications:

- Printing Industry: Bundling of brochures, magazines, books, and other printed materials.

- Packaging: Securing products in transit, such as boxed goods or palletised items.

- Logistics: Bundling shipments for streamlined transport and handling.

- Retail: Creating ready-to-sell bundles for retail environments, including promotional materials or products.

Benefits:

- Increased Productivity: High-speed operation ensures efficient bundling with minimal manual intervention.

- Customization: Flexible settings and banding options cater to diverse product needs.

- Cost-Effective: Low power consumption and minimal maintenance reduce operational costs.

- Environmentally Friendly: Supports eco-friendly banding materials, contributing to sustainable practices.

Maintenance & Support:

- Maintenance: Low-maintenance design with easy access to all components for quick servicing.

- Support: Comprehensive customer support and service options, including on-site assistance and remote troubleshooting, are available on request

Specifications

| Manufacturer | Busch |

| Model | TB26 I & II Banding machine |

| Condition | New |

| Stock Number | 000000000 |

| Operation Mode: | Semi-automatic with a foot pedal or automatic start/stop functionality |

| Banding Material: | Paper or polypropylene bands |

| Cycle Time: | Approx. 1.5 seconds per cycle (depending on the band type and material) |

| Bundle size: | Maximum bundle size of 330mm (width) x 210mm (height) |

| Dimensions (W x H x D): | 610mm x 460mm x 520mm |

| Noise Level: | Less than 75 dB, ensuring a quieter operation suitable for various work environments |

| Power Supply: | 230V, 50/60Hz |

| Power Consumption: | 0.3 kW |

| Weight | 75 kg |