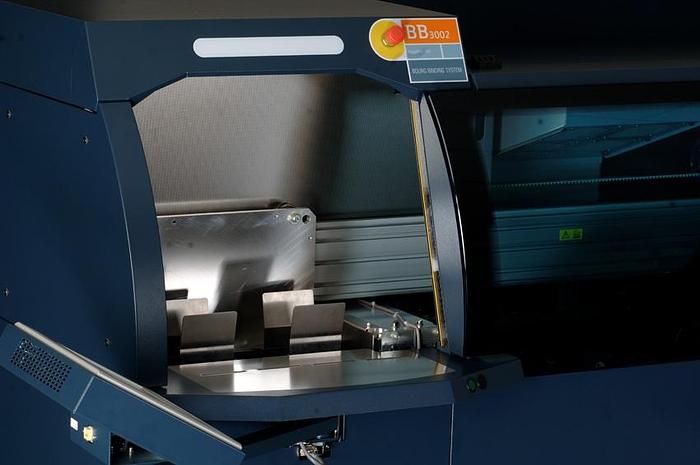

CP Bourg BB3002 Perfect Binder

CP Bourg BB3002 Perfect Binder

Description

The BB3002 Perfect Binder is the most user-friendly system to produce the highest quality bound books applications. Built to handle heavy production environments, whether in line with a printer*, a BSF Sheet Feeder, or a BBL Book Loader. It can handle a large range of formats up to 385 x 750 mm (15.15 x 29.52 in) and has a maximum rated speed of 600 cycles per hour**. The BB3002 also offers a wide selection of configurations, allowing you to bleed/trim, crease, cut, fold, and perforate any job. These features enable 2-up/4-up job processing via our ergonomic touch screen and barcode reading systems, automatically adjusting to pre-saved jobs or JDF/JMF workflows.

Graphical User Interface - GUI

The intuitive colour GUI is icon-based for user-friendly operation. It is ergonomically designed to swing left or right for operator preference. All machines' setups are managed and stored for toolless operation.

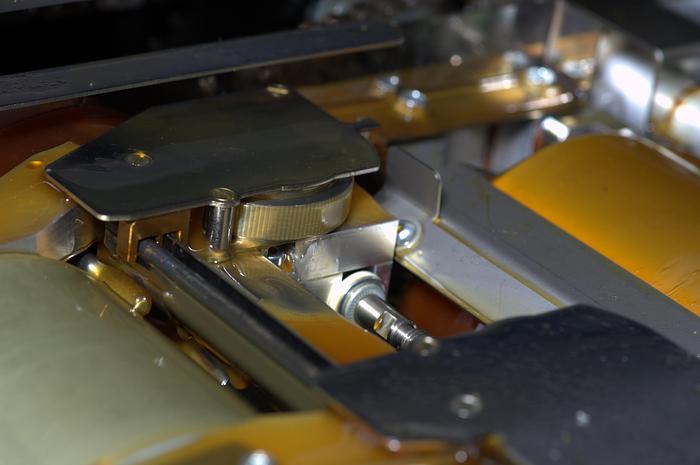

Jogging and Caliper

The bi-directional book block jogger aligns and registers the individual book pages. Simultaneously, the carriage clamp/caliper automatically detects the book block thickness and instantly sets up the binding processes and cover creasing, ensuring the delivery of high-quality finished books.

Milling

Powerful motor-driven milling blade with up to 4 notching knives that prepare the EVA or PUR spine of the book block or signatures for optimum glue penetration and adhesion. Milling speed and depth can be adjusted automatically according to book block thickness from 0 to 3 mm (0 to 0.11").

EVA Gluing

Our EVA Smart tank technology is equipped with dual applicators/cylinders, heated back spinning and knurled side gluing rollers, automated glue start-and-stop cutoffs, and an adhesive tank level indicator.

Clamping / Nipping

A powerful clamping/nipping module guarantees precise registration of the cover as it is applied to the book block, automatically producing flat square spines on books of variable size and thickness.

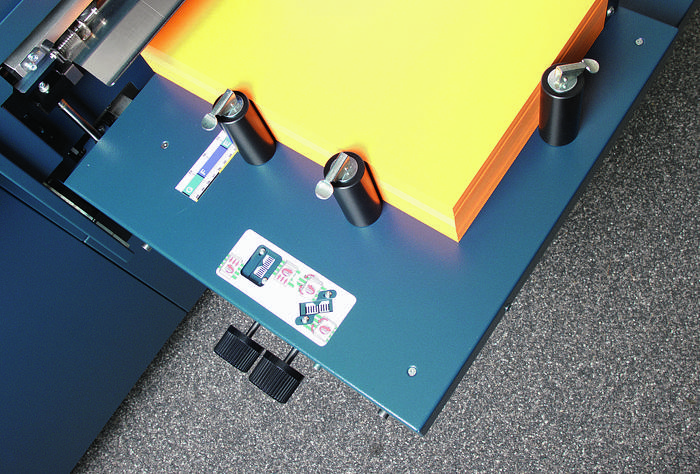

Cover Feeding

Our ergonomically positioned cover feeder is directly in the operator's "line of sight" and features self-adjusting air and vacuum, load-while-run capability, double and miss detection, and a large capacity of 80 mm (3.5") with onboard cover askew and registration adjustments.

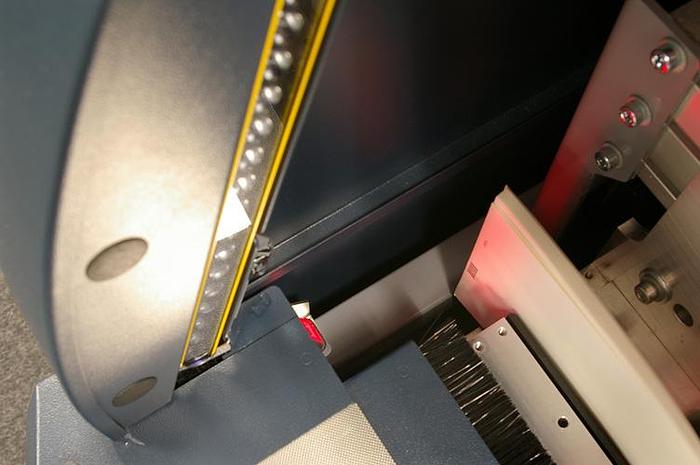

Cover Creasing / Scoring

Our true knife cover creasing technology guarantees we don’t delaminate or skew the cover. Compared to wheel scoring, knife creasing offers cleaner, superior-quality results and avoids damaging the printed surface or cracking the cover. The BB3002 comes with up to 13 positive and negative creases on the cover, ideal for books with flaps.

Barcode Scanning

Optional barcode scanning can be added of a BB3002 perfect binder, whether it is connected to a BBC compiler or to a BBL loader. This allows the system to read job information for a guaranteed job integrity and sequence. Data extraction is available.

Specifications

| Manufacturer | CP bourg |

| Model | BB3002 Perfect Binding machine |

| Condition | New |

| Stock Number | 000000000 |

| Cycle Time: | Up to 600 cycles / Hr |

| Speed range: | Up to 400 books / Hr |

| Working sizes: | From 100 x 100 x 1 mm To 380 x 385 x 60 mm (L x W x H) |

| Minimum Cover size: | 100 x 201 mm (3.93 x 7.91 in) |

| Maximum Cover Size: | 385 x 750 mm (15.15 x 29.52 in) |

| Cover weight: | 80 to 300 gsm |

| Minimum paper size of books with cover (perfect binding mode): | 100 x 90 mm (3.93 x 3.54 in) |

| Maximum paper size of books with cover (perfect binding mode): | 385 x 380mm (15.15 x 14.96 in) |

| Minimum paper size of books without cover (padding mode): | 60 x 90 mm (2.36 x 3.54 in) |

| Maximum paper size of books without cover (padding mode): | 385 x 320 mm (15.15 x 12.59 in) |

| Book thickness: | 1 to 60 mm (0.04 to 2.36 in) |

| Milling depth: | 0 to 3 mm (0 to 0.11 in) |

| Paper weight: | 60 to 160 gsm |

| Dimensions (L x W x H): | BB3002:- 202 x 135 x 150 cm (79.52 x 53.15 x 59.05 in) |